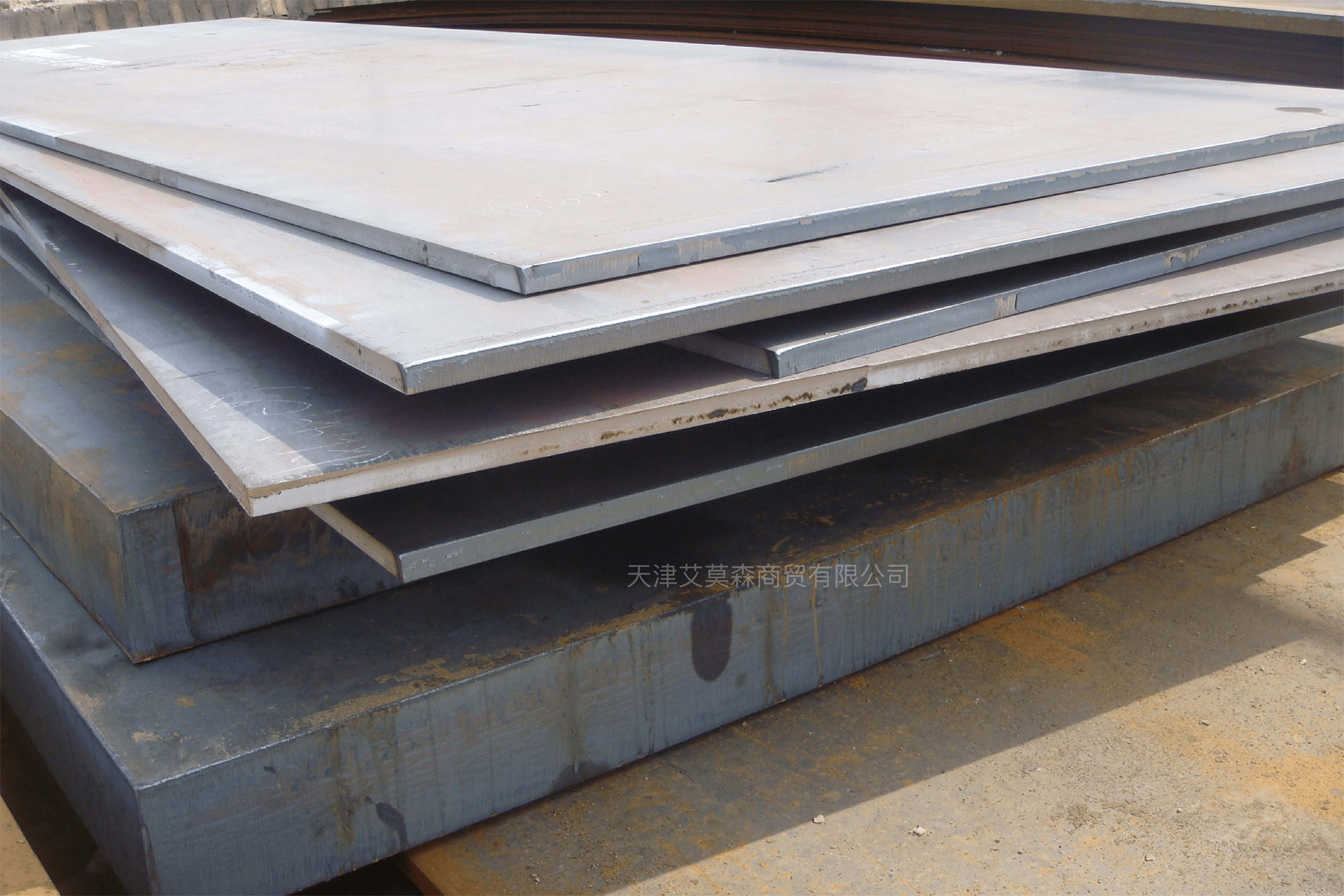

为您提供优质的钢材和加工服务

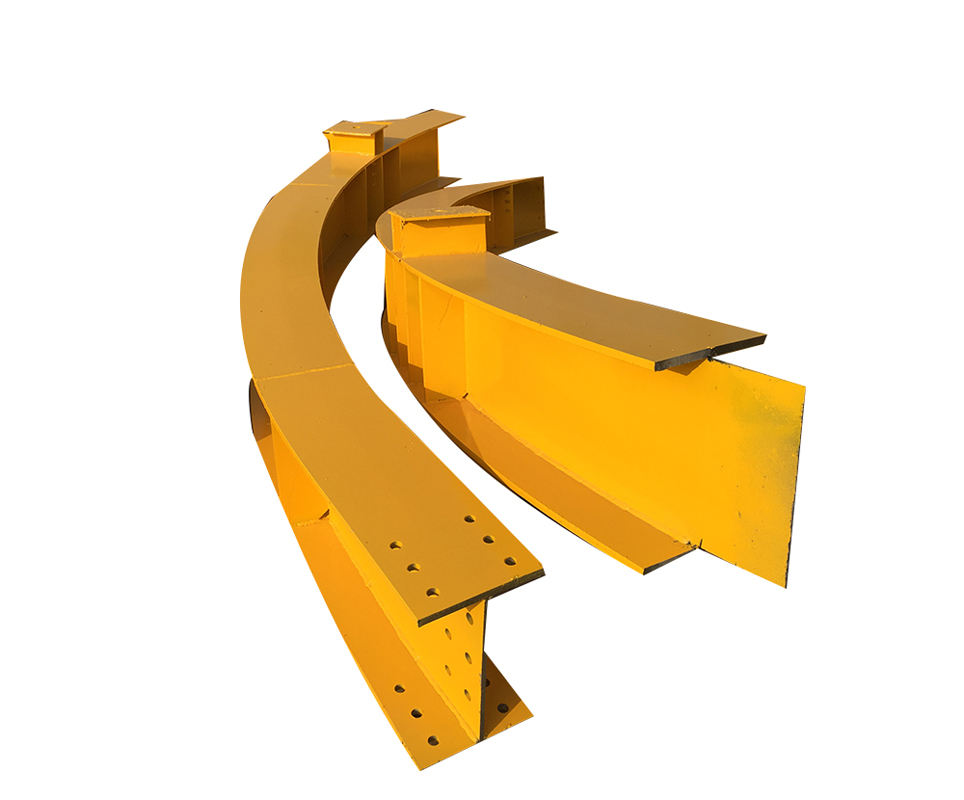

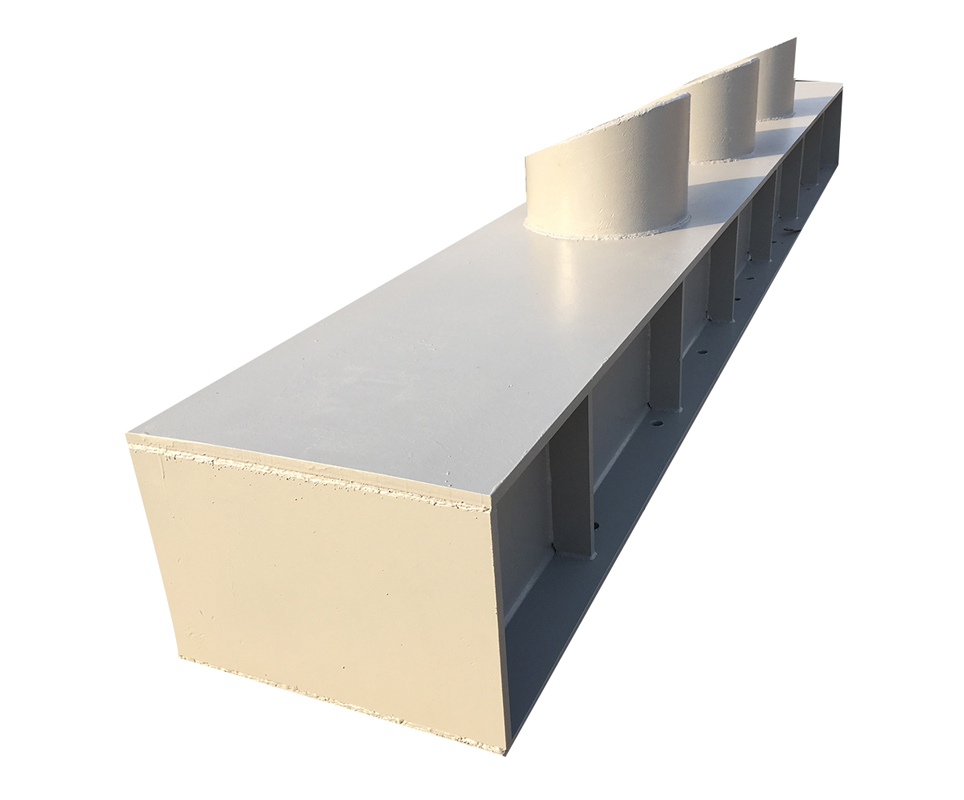

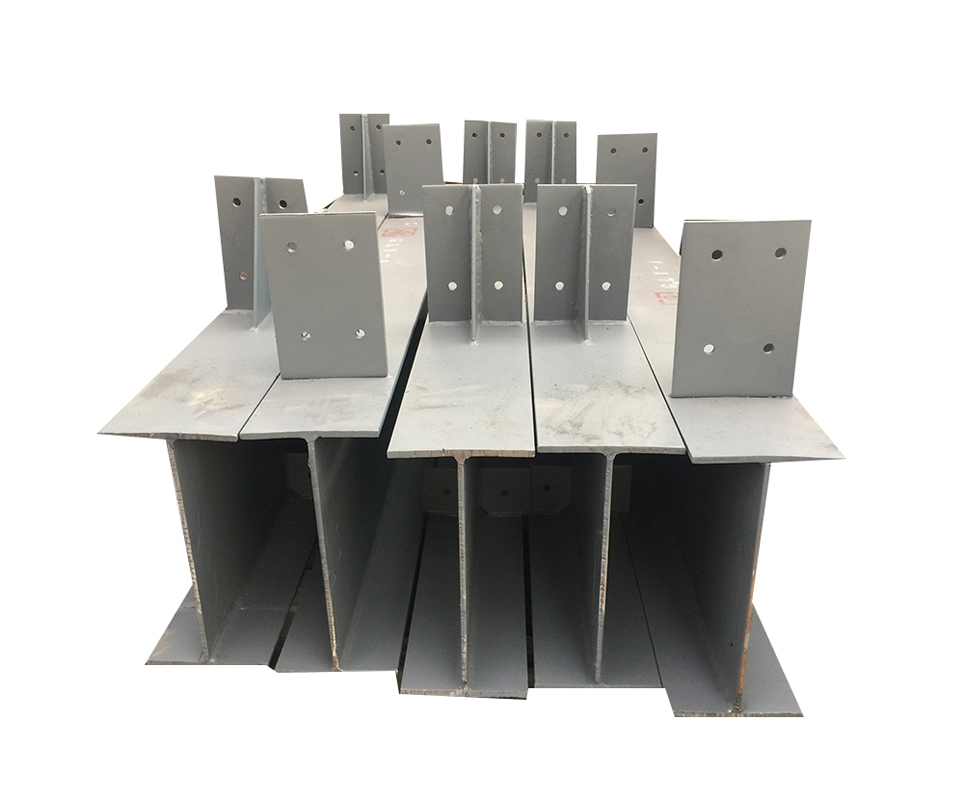

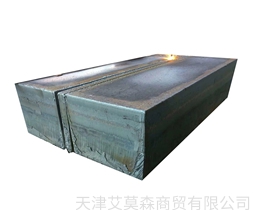

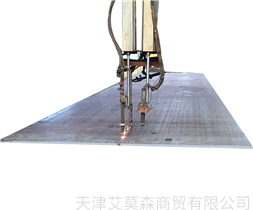

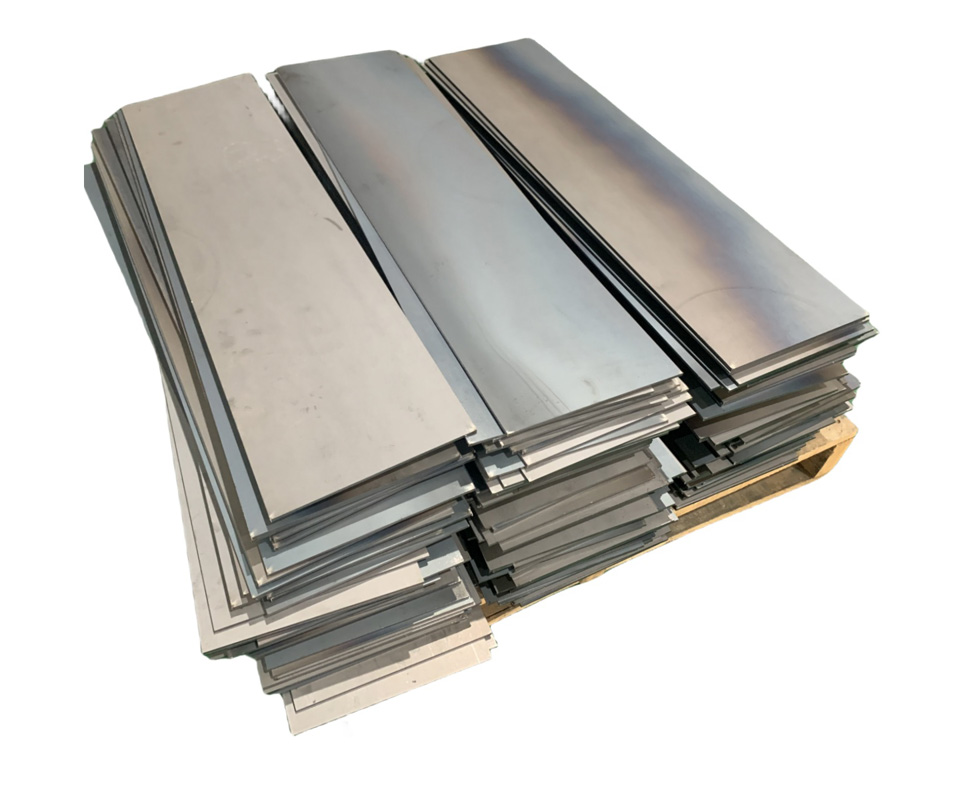

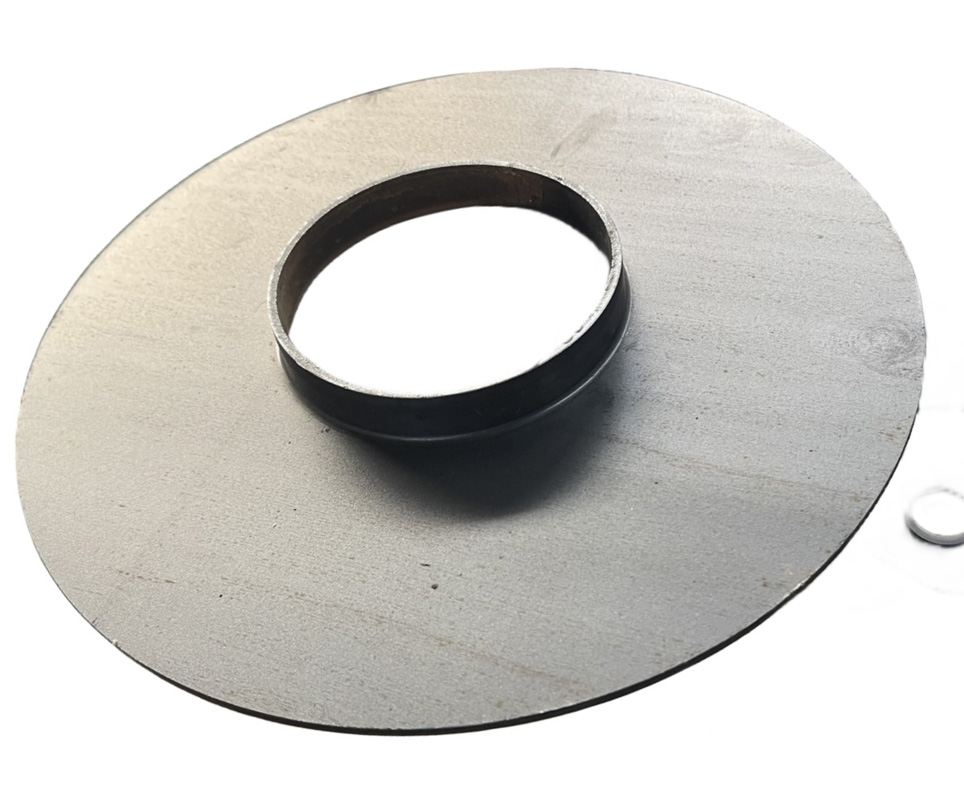

天津艾莫森提供热轧卷板, 冷轧卷板, 镀锌卷板,镀铝锌镀镁铝卷板,彩涂卷板, 不锈钢卷板等卷材,提供热轧钢板,中厚板,冷轧钢板, 镀锌钢板,镀铝锌钢板,不锈钢薄板,不锈钢中厚板等板材;除卷材和板材以外还可提供管材,无缝钢管,厚壁管,焊管, 镀锌钢管,方矩管,异型管等管材;另外还可以提供优质特钢, 热轧圆钢,冷拉圆钢, 锻造圆钢,热轧方钢,冷拉方钢,热轧扁钢,冷拉扁钢,六角钢,工字钢,H型钢,角钢,槽钢等型材;除原材料以外还可以提供金属钣金加工服务,钢板火焰切割,CNC数控切割,激光切割,水刀切割,按照客户图纸进行加工定制;钢管折弯,切割,焊接,喷砂抛丸,喷漆,镀锌等钢管加工服务;圆钢热处理, Q+T调质热处理,车削,剥皮以及圆钢车丝等机加工服务,可根据图纸进行各类加工;型材折弯,焊接以及钢结构钢构件,五金冲压件加工服务。

MORE + 天津艾莫森

天津艾莫森